TLL-300

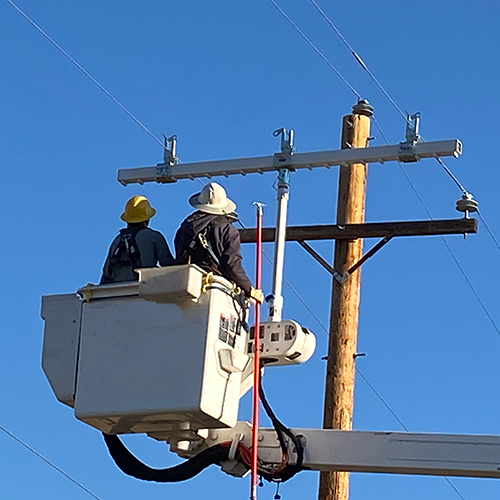

The distribution arm is an economical arm that attaches to a digger derrick or bucket truck for distribution work below 34.5kV.

CLICK FOR RENTAL INFOFeatures

- TLL-300B direct replacement for competitor’s Three Phase Lift Assembly

- TLL-300B mounts to material handling jib of bucket truck

- Crossarm is pinned to the mast.

- Crossarm can rotate 15 degrees each direction from 0 degrees (in line with the boom) and also 15 degrees each direction from 90 degrees to the boom

- Crossarm & mast are composed of fiberglass for di-electric properties

- 10-minute set up time = 2 linemen and no tools required

- Fiberglass is sealed using LineWise desiccant canister system

- No cross bracing required

- 3 wire holder options:

- Standard Wire Holder

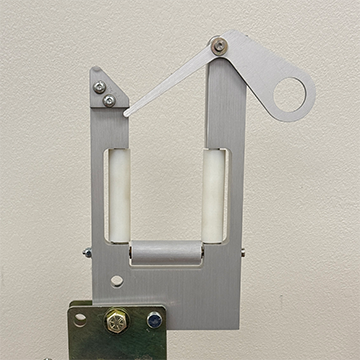

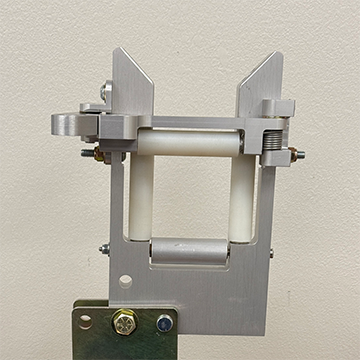

- Roller Wire Holder

- Swing Gate Wire Holder

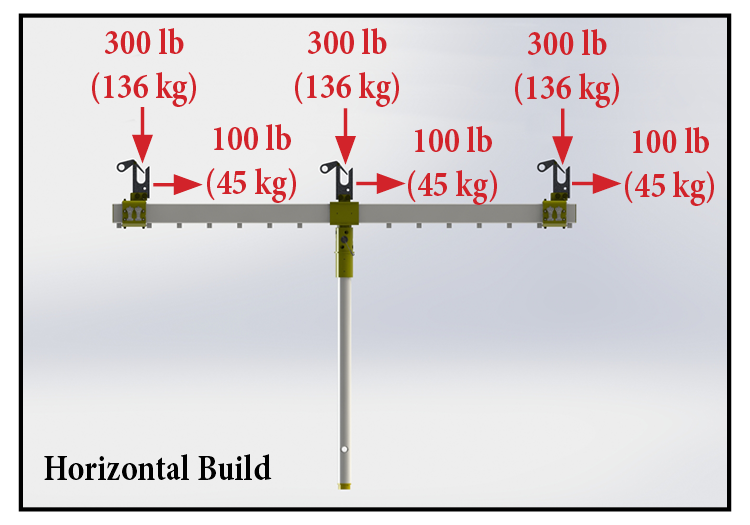

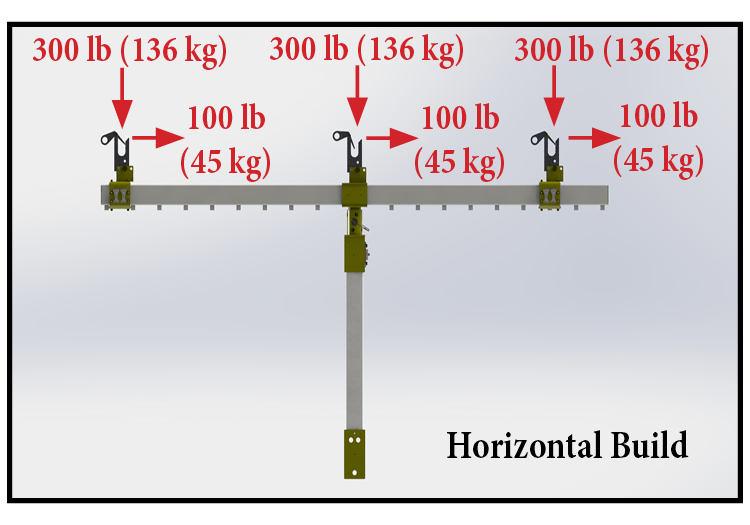

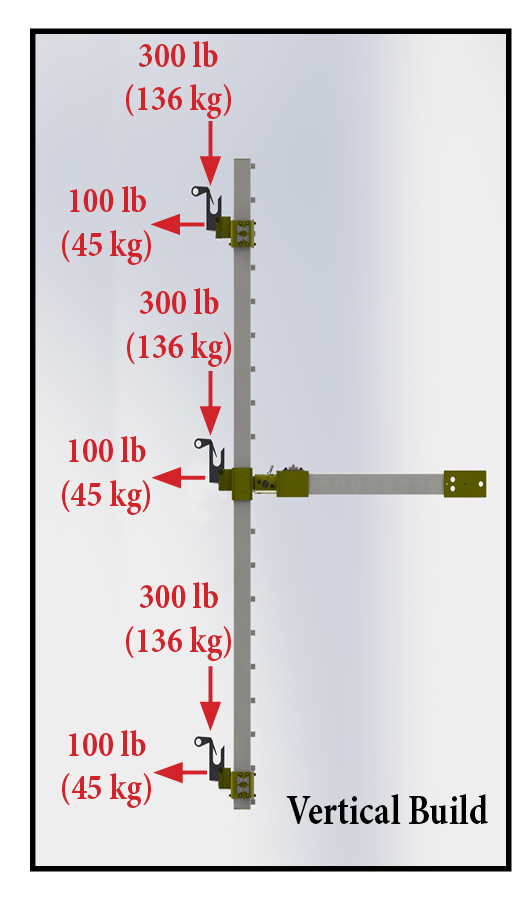

- 300 lb (136 kg) downward load

- 300 lb (136 kg) side load

- 100 lb (45 kg) gate load

Specifications

| TLL-300B | TLL-300D | |

|---|---|---|

| Voltage (#) Phases up to 34.5 kV (3) phases | Capacity per position 300 lb (136 kg) per position 900 lb (408 kg) total 100 lb (45 kg) horizontal load per position 300 lb (136 kg) total horizontal load per position | Capacity per position 300 lb (136 kg) per position 900 lb (408 kg) total 100 lb (45 kg) horizontal load per position 300 lb (136 kg) total horizontal load per position when using the 31’’ (787 mm) clear span mast |

| Max. Phase Spacing Outside to Outside Center to Outside | 7’ 6’’ (2286 mm) 3’ 9’’ (1143 mm) | 9’ 4’’ (2845 mm) 4’ 8’’ (1422 mm) |

| Min. Phase Spacing Outside to Outside Center to Outside | 1’ 7’’ (483 mm) 8’’ (203 mm) | 1’ 6’’ (457 mm) 11’’ (279 mm) |

| Total unit weight (Approx.) | 8’ (2438 mm) crossarm with 32’’ (813 mm) clear span mast 110 lb (50 kg) | 10’ (3048 mm) crossarm with 12’’ (305 mm) mast 135 lb (61 kg) 10’ (3048 mm) crossarm with 31’’ (787 mm) mast 146 lb (66 kg) plus 250-300 lb (113-136 kg) for the adapter |

| Phase to Ground | 32’’ (813 mm) clear span fiberglass | 12'' (305 mm) clear span fiberglass 31'' (787 mm) clear span fiberglass |

| Hydraulic Articulation | No, manual adjustment only | No, manual adjustment only |

| Lift Device/Crane Needed | Bucket Truck Material Handling Jib | Digger Derrick |

Wire Holder Options

Standard Wire Holder

Roller Wire Holder

Swing Gate Wire Holder

The TLL-300D can accommodate vertical and horizontal construction

The TLL-300B is used for horizontal construction only