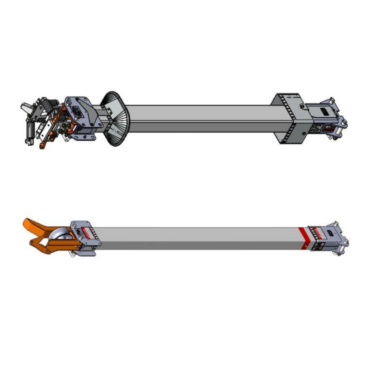

Fiberglass Insulators

Fiberglass insulators are high-strength electrical insulating components made from fiberglass-reinforced plastic (FRP). They’re designed to support and electrically isolate conductors in power systems like transmission lines, substations, and distribution networks. LineWise has a variety of insulators, with ratings from 69 kV to 345 kV.

FeatureS

- Test Band

- Corona Ring

- Arrows for Insulated Area

- Desiccant Canister System

- Dielectric Testing

- Clear Span Fiberglass

- Vinyl Fiberglass Covers

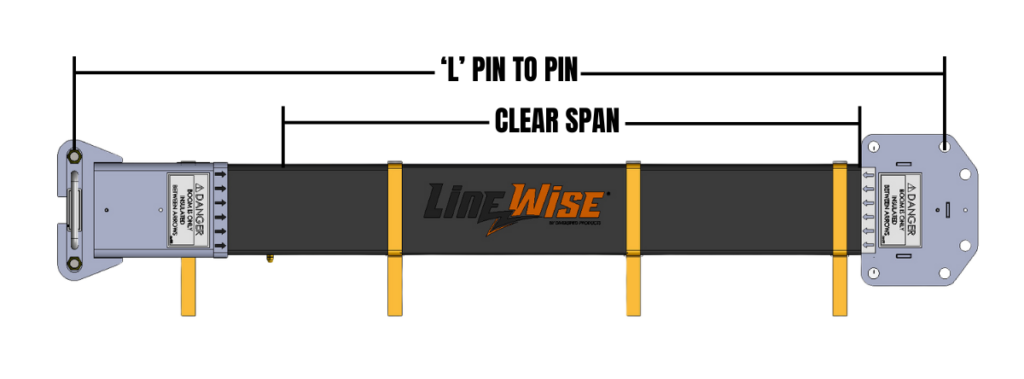

Specifications

| Clear Span | Weight | L' Pin-to-Pin | |

|---|---|---|---|

| 69 kV | 35 1/2'' | 55.42 lb | 57 9/16'' |

| 115 kV | 40 1/2'' | 55.42 lb | 62 9/16'' |

| 138 kV | 47 1/4'' | 57.68 lb | 69 5/16'' |

| 161 kV | 55'' | 71.46 lb | 81 1/16'' |

| 230 kV | 74'' | 78.30 lb | 100 1/16'' |

| 345 kV | 120 1/8'' | 252.64 lb | 152 5/8'' |

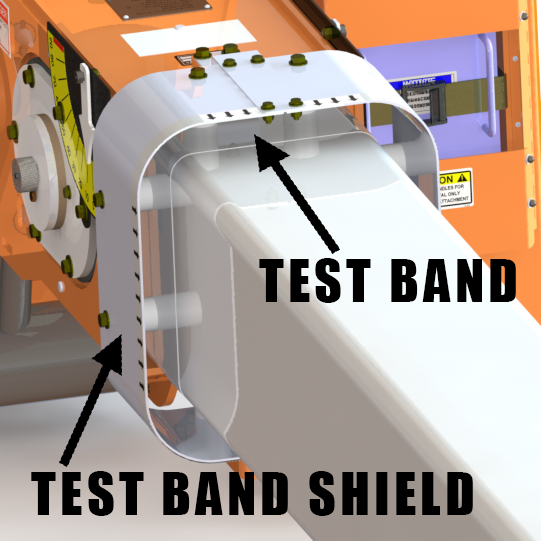

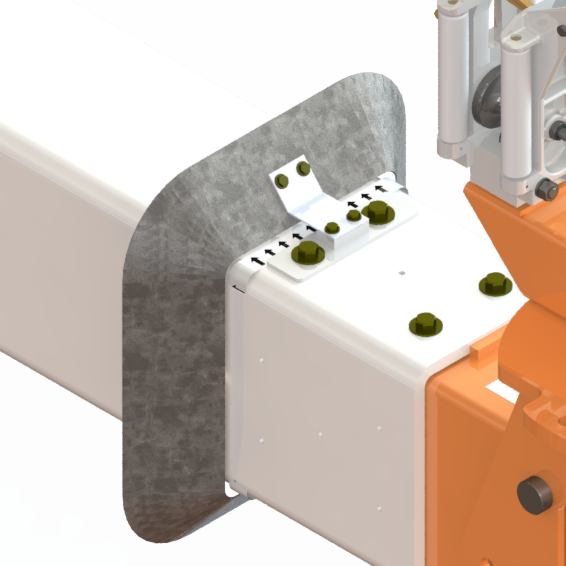

Test BanD & TEST BAND SHIELD

The test band inside and outside on a fiberglass insulator is a designated area used for dielectric testing to ensure the boom maintains its insulating properties and measures surface dielectrical leakage.

The test band shield serves as a protective cover for the test band area, helping to maintain its dielectric integrity by preventing contamination or damage.

Purpose of the Test Band

- Dielectric Testing – The test band is where periodic electrical insulation tests are conducted to verify that the boom still meets safety standards.

- Compliance with Standards – Meets ANSI and OSHA requirements for testing devices used in utility and electrical work.

- Arrows for Insulated Area – A visual indicator of the area that needs to clean and free of contaminants like dirt, moisture, or oil, which could compromise the insulating performance.

Purpose of the Test Band Shield

- Protects the Test Band – Shields the designated dielectric test area from dirt, moisture, and other contaminants that could degrade insulation properties.

- Extends Boom Lifespan – Reduces wear and environmental exposure, helping the fiberglass boom maintain its structural and electrical integrity over time.

- Facilitates Accurate Dielectric Testing – Keeps the test band in optimal condition for periodic electrical testing, ensuring compliance with ANSI A92.2 and OSHA regulations. Minimizes any corona discharge from test data.

Corona RIng

A corona ring on a fiberglass insulator serves to reduce electrical stress and prevent corona discharge at high voltages. It ensures the reliability, longevity, and safety of fiberglass booms used in high-voltage line-line work. Specifically, it:

- Minimizes Corona Discharge – Corona discharge occurs when high-voltage electric fields ionize the surrounding air, leading to energy loss, audible noise, and electromagnetic interference. The corona ring helps distribute the electric field more evenly, reducing localized high field intensities that could cause ionization.

- Enhances Insulation Performance – Fiberglass booms are used in live-line maintenance because of their insulating properties. However, without a corona ring, high voltage can concentrate at sharp edges or terminations, potentially leading to premature degradation of the boom’s insulation.

- Extends Equipment Life – By preventing localized electric field stress, the ring helps extend the service life of the fiberglass boom by reducing the risk of electrical breakdown, surface tracking, and material degradation.

- Improves Safety – High-voltage corona discharge can lead to unpredictable electrical behavior, including flashovers. The corona ring helps manage the electric field, reducing the risk of unintended electrical discharge near workers.

Desiccant Canister System

A desiccant canister system is a moisture-control device used to protect the insulating properties of fiberglass booms on trucks. These systems help prevent moisture accumulation, which can degrade the dielectric (insulating) properties of the boom and lead to electrical hazards.

How It Works:

- Moisture Absorption: The canister contains a desiccant material (such as silica gel or activated alumina) that absorbs moisture from the air inside the boom.

- Humidity Regulation: By keeping the internal environment dry, the system prevents condensation and water retention inside the boom structure.

- Visual Indicator: LineWise desiccant canisters include a color-changing indicator that alerts users when the desiccant is saturated and needs replacement. If the silica is blue, no moisture is detected. If the silica is pink, then moisture is detected, and the silica needs to be replaced. The insulator also needs to be inspected/cleaned of any moisture.

Why It’s Important for Fiberglass Booms:

- Prevents Electrical Conductivity: Moisture buildup inside the boom can compromise its insulating properties, increasing the risk of electrical arcing.

- Extends Boom Life: Reduces internal corrosion or degradation caused by prolonged exposure to humidity.

- Maintains Safety Standards: Ensures compliance with OSHA and ANSI safety regulations by preserving the boom’s insulating integrity.

Maintenance Considerations:

- Regularly inspect the desiccant canister and replace it when the color changes.

- Ensure the canister is properly sealed to maintain effectiveness.

- Check for moisture intrusion points in the boom, such as cracks or worn seals.

- Inspect and clean the interior of the boom.

- I

Dielectric Testing

Dielectric testing of fiberglass booms is a crucial procedure to ensure the electrical insulation integrity of an insulating device used in utility work, especially for linemen working on live electrical lines. Here’s an overview of the key aspects:

Purpose of Dielectric Testing

- Ensures the electrical insulating properties of fiberglass booms meet safety standards.

- Detects moisture absorption, contamination, and damage that could compromise insulation.

- Helps comply with OSHA and ANSI safety regulations.

Standards & Regulations

- ANSI A92.2 – Governs the dielectric testing of insulating aerial devices.

- OSHA 1910.67 & 1926.453 – Mandates periodic testing and maintenance.

- Manufacturer Guidelines – Specific test procedures may vary based on boom/insulator design.

Testing Frequency

- Initial (Acceptance) Testing – Performed when the boom/insulator is new.

- Periodic Testing – LineWise insulators are tested every 2 years.

- Post-Repair Testing – Required after structural or electrical repairs.

Testing Procedure

- Preparation

- Clean the boom thoroughly as described in the manual to remove dirt, oil, and contaminants.

- Inspect for cracks, wear, or moisture intrusion.

- Ensure proper environmental conditions (low humidity, dry surface).

- Voltage Application

- A high-voltage AC or DC test is applied to the fiberglass boom/insulator.

- Standard test voltage for AC is defined in ANSI in the manual.

- DC testing may be used as an alternative but is less common.

- Leakage Current Measurement

- The current leakage is measured to ensure it is within acceptable limits.

- Excessive leakage indicates contamination, moisture absorption, or material degradation.

- Pass/Fail Criteria

- If the leakage current exceeds the specified threshold, the boom fails and requires repair or replacement.

- If there is a flashover, the insulator fails and requires repair or replacement.

Common Causes of Failure

- Moisture Ingress – Absorption due to cracks or prolonged exposure to wet conditions.

- Surface Contamination – Dirt, oil, and conductive residues can degrade insulation.

- Structural Damage – Cracks or delamination weaken the dielectric properties.

Maintenance & Best Practices

- Regular Cleaning – Use non-conductive cleaning agents (refer to manual).

- Boom Storage – Keep dry and covered when not in use.

- Preventative Inspections – Identify issues before formal testing.

Vinyl Covers

Vinyl covers serve as a protective outer layer for LineWise fiberglass insulators, shielding it from environmental exposure, moisture, UV rays, and physical damage.

Benefits

- Weather Resistance – Vinyl protects against rain, snow, blowing sand, and extreme temperatures, extending the life of the insulation.

- Durability – Resists tearing, punctures, and abrasions, ensuring long-term use in harsh conditions.

- Moisture Barrier – Prevents water infiltration that could degrade fiberglass insulation.

- UV Protection – Reduces exposure to sunlight, preventing material breakdown over time.

- Easy Maintenance – Smooth, wipeable surface allows for simple cleaning and upkeep.

- Flexibility – Can be customized for different shapes, sizes, and applications.